- Home

-

About Us About Us

Li Tongwei Electronics Technology Co., Ltd. was established on September 29, 2005. It is a professional lithium-battery protection module, lithium-powered battery protection module, single-chip microcomputer control intelligent lithium-powered battery balanc...

View More- company profile

- Company Honours

- Company style

- enterprise culture

- Organizational structure

- Development history

The development of the company has entered the fast track and has maintained a high rate of growth for many years, which has aroused continuous concern from all walks of life.

-

Products Products

Shenzhen Litongwei Electronic Technology Co., Ltd. provides you with a comprehensive solution which integrates service and technical support.

View More

Shenzhen Litongwei Electronic Technology Co., Ltd. provides you with a comprehensive solution which integrates service and technical support.

-

Supports Supports

The group adhering to the "forever service value, improve the quality of service" service concept, service attitude, perfect service network, skilled technology, sincere service for the implementation of the "professional to create value, service customer...

View More

The scope of business involves a number of countries in the world, market share, brand influence, trade growth, service network coverage and quality of service has become the dominant industry.

- Privacy policy

-

News

News

The company upholds the service concept of "let service always exceed value for money and improve service quality", and achieves the service goal of "creating value by profession and touching customers by service" with perfect service network, ski...

View More

Business scope covers many countries in the world. Market share, brand influence, growth rate of trade volume, coverage of service network and service quality have become benchmarks of the same industry.

-

LTW Culture LTW Culture

Human resources management policy: Acknowledging human needs, attaching importance to human values, developing human potential and encouraging human creation. Human resources management objectives: People-oriented—— Create fair opportuniti...

View More

We have been committed to creating the best work and development platform for outstanding talents.

-

Contact Us Contact Us

Shenzhen Litongwei Electronic Technology Co., Ltd. Address: Building C, Beverly Industrial Park, Longhua Dalang Street, Shenzhen Contact number: 0755-81489958 Fax: 0755-81489955 The NEW English Website: www.ltw-bms.com Mobile phone: +86-13823387...

View More

您可以用多种方式联系我们。我们会尽我们所能为您服务!

Industry developments

Industry developments

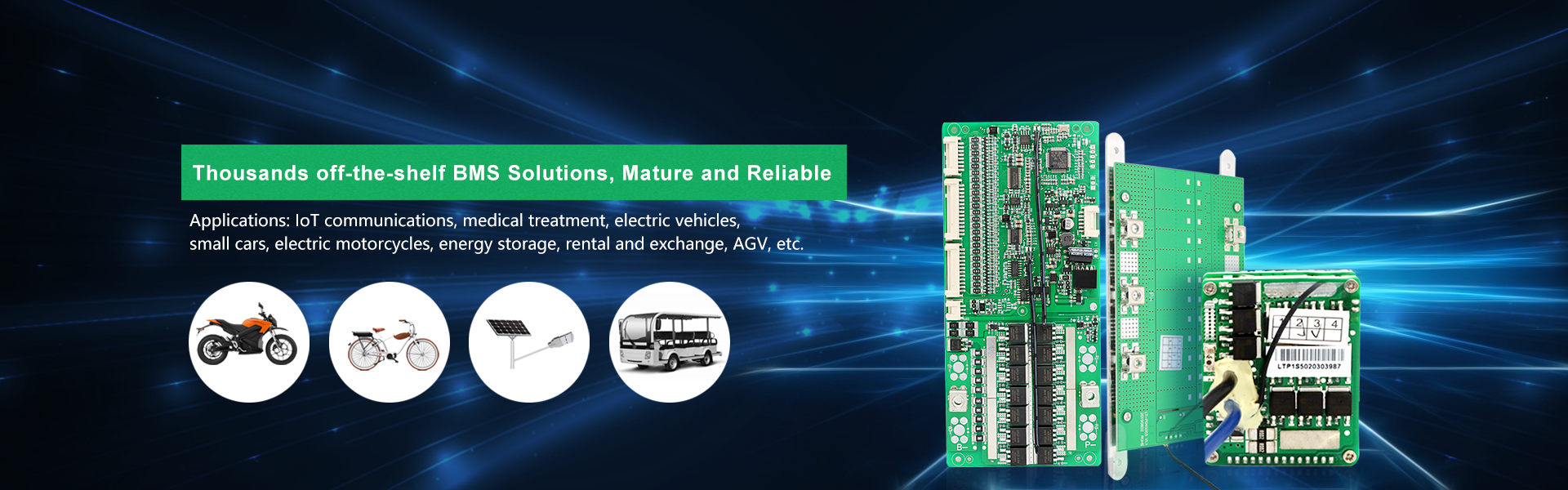

Li Tongwei Electronics Technology Co., Ltd. was established on September 29, 2005. It is a professional lithium-battery protection module, lithium-powered battery protection module, single-chip microcomputer control intelligent lithium-powered battery balance protection module, battery management system(BMS), and lithium battery terminal application product UPS, emergency power supply, automotive backup power supply, Mobile base station, electric vehicle BMS, mobile power supply and other R&D, production, sales and service of national high-tech enterprises.

The company has now passed the ISO 9001:2015 quality management system, the ISO 14001:2015 environmental quality management system, the QC080000 harmful substances management system,...

Li Tongwei Electronics Technology Co., Ltd. was established on September 29, 2005. It is a professional lithium-battery protection module, lithium-powered battery protection module, single-chip microcomputer control intelligent lithium-powered battery balance protection module, battery management system(BMS), and lithium battery terminal application product UPS, emergency power supply, automotive backup power supply, Mobile base station, electric vehicle BMS, mobile power supply and other R&D, production, sales and service of national high-tech enterprises.

The company has now passed the ISO 9001:2015 quality management system, the ISO 14001:2015 environmental quality management system, the QC080000 harmful substances management system,...