Balancing Principle of Lithium Battery Protection Plate

When batteries are charged in series, they should be charged equally, otherwise the performance and life of batteries will be affected. The commonly used equalization charging technologies include constant shunt resistance equalization charging, on-off shunt resistance equalization charging, average battery voltage equalization charging, switched capacitor equalization charging, buck converter equalization charging, inductance equalization charging, etc. The existing single lithium battery protection chip does not include the balanced charging control function; the balanced charging control function of multi-lithium battery protection chip needs external CPU, which is realized by serial communication with the protection chip (such as I2C bus), which increases the complexity and design difficulty of the protection circuit, reduces the efficiency and reliability of the system, and increases power consumption.

In view of the principle of balancing power lithium batteries using lithium battery protection board in groups, each lithium battery requires protection of charging overvoltage, discharging undervoltage, overcurrent and short circuit, and realizing balanced charging of the whole battery during charging, this paper introduces a battery with balanced charging function, which uses a single lithium battery protection chip to protect any series number of lithium batteries. Design scheme of group protection board. The simulation results and industrial application prove that the protective function of the protective board is perfect, the work is stable and the performance-price ratio is high.

The commonly used equalization charging technologies of lithium battery protection plate equalization principle include constant shunt resistance equalization charging, on-off shunt resistance equalization charging, average battery voltage equalization charging, switched capacitor equalization charging, step-down converter equalization charging, inductance equalization charging, etc. When a group of lithium batteries are charged in series, it should be guaranteed that each batteries are charged equally, otherwise the performance and life of the batteries will be affected in the use process. The existing single lithium battery protection chip does not include the balanced charging control function, and the balanced charging control function of multiple lithium battery protection chips needs external CPU. By serial communication with the protection chip (such as I2C bus), the complexity and design difficulty of the protection circuit are increased, the efficiency and reliability of the system are reduced, and the power consumption is increased.

In view of the group use of power lithium batteries, the protection of overvoltage, discharge undervoltage, overcurrent and short circuit is required for each lithium batteries. In order to realize the balanced charging of the whole batteries during the charging process, this paper introduces a design of a battery pack protection board with balanced charging function, which uses a single lithium battery protection chip to protect any series number of batteries. The simulation results and industrial application prove that the protective board has perfect protection function, stable operation, high performance-price ratio and less than 50 mV equalization charging error.

1. Principle and Structure of Balanced Charging for Protective Plate of Lithium Battery

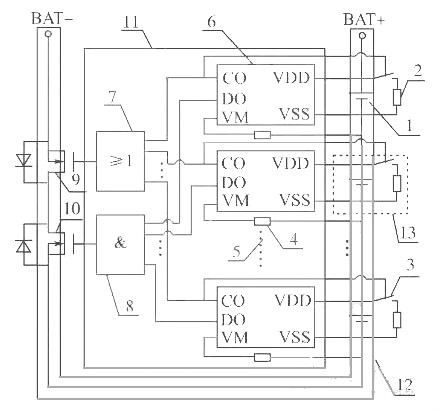

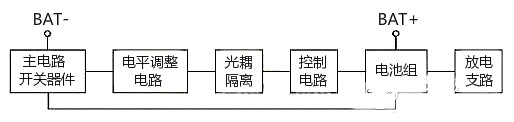

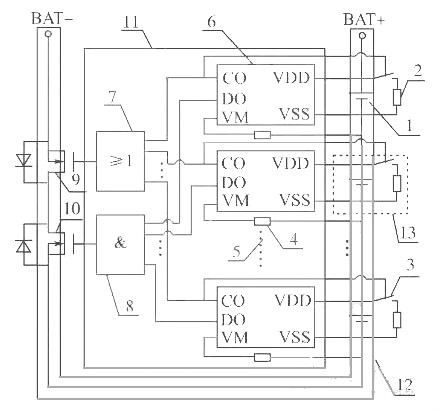

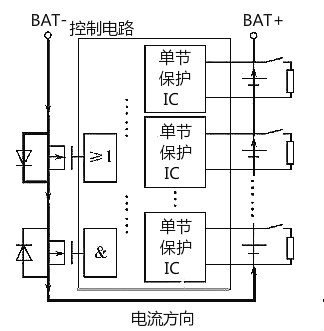

A single lithium battery protection chip is used to design a protective board for lithium battery packs with balanced charging capability. The block diagram of the protective board is shown in Figure 1 below.

Fig. 1 Structural block diagram of protective plate for lithium battery pack

Among them: 1 is a single lithium-ion battery; 2 is a branch resistance for charging overvoltage shunt discharge; 3 is a switch device for shunt discharge branch control; 4 is an overcurrent detection protection resistance; 5 is an omitted lithium battery protection chip and circuit connection; 6 is a single lithium battery protection chip (generally including charging control pin CO, discharge control pin DO, discharge overcurrent and short circuit detection pin VM, electricity). VDD at the positive end of the battery and VSS at the negative end of the battery, etc., 7. The over-voltage protection signals are separated by optocoupler to form a parallel connection to drive the gate of MOS transistor for charge control in the main circuit, 8. The equalization principle of lithium battery protection board is that under-voltage, over-current and short-circuit protection signals are separated by optocoupler to form a series connection to drive the gate of MOS transistor for discharge control in the main circuit, and 9 is a charge control switch device. For the discharge control switch device; 11 for the control circuit; 12 for the main circuit; 13 for the shunt discharge branch. The number of single lithium battery protection chips is determined according to the number of lithium battery packs. They are used in series to protect the charge-discharge, over-current and short-circuit states of the corresponding single lithium battery. While charging and protecting, the system realizes balanced charging by controlling the on-off of shunt discharge branch switch devices with protection chip. This scheme is different from the traditional balanced charging method at the charger end, and reduces the cost of design and application of lithium battery charger.

2 Hardware design

2.1 Charging Circuit

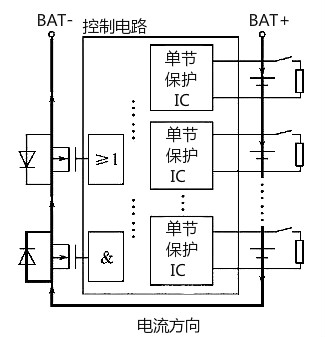

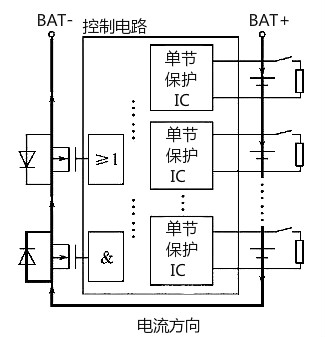

When the lithium battery pack is charged by the protection plate equalization principle of lithium battery, the positive and negative poles of the external power supply are connected to the positive and negative poles of the battery pack respectively, and the charging current flows through the positive and negative poles of the battery pack BAT+, the single lithium battery 1~N in the battery pack, the discharge control switch device, the charging control switch device and the negative pole BAT of the battery pack.-The current flow is shown in Figure 2.

Fig. 2 Charging circuit of lithium battery pack

In the control circuit part of the system, the charging overvoltage protection control signal of a single lithium battery protection chip is output in parallel after optocoupler isolation, which provides gate voltage for the conduction of charging switching devices in the main circuit. If one or several lithium batteries enter the overvoltage protection state first in the charging process, the protection plate equalization principle of lithium battery is controlled by the overvoltage protection signal in parallel in a single lithium battery. At the same time, the corresponding single lithium battery connected in series in the charging circuit is disconnected from the charging circuit.

2.2 Main Circuit and Diversion Discharge Branch

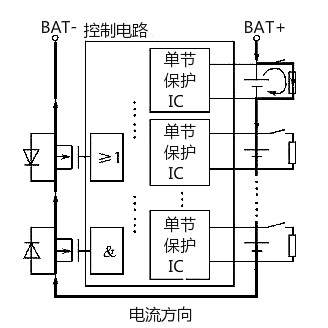

When lithium batteries are charged in series, the influence of capacity difference of single battery is neglected. Generally, batteries with smaller internal resistance are filled first. At this time, the corresponding over-voltage protection signal controls the switching device of shunt discharge branch to close, and a shunt resistance is connected in parallel at both ends of the primary battery. According to the PNGV equivalent circuit model of the battery, the shunt branch resistance is equivalent to the load of a single lithium battery filled at first. The battery maintains its terminal voltage in a very small range near the full state by discharging. Assuming that the first lithium battery charges first and enters the overvoltage protection state, the current flow in the main circuit and the shunt discharge branch is shown in Figure 3. When all single batteries are charged into overvoltage protection state, the voltage of all single lithium batteries is equal within the error range. The charge protection control signals of each protection chip become lower. It is impossible to provide gate bias for charging control switch devices in the main circuit to turn off the main circuit and disconnect the main circuit, that is, to realize balanced charging and overcharge. Cheng completed.

Figure 3 Main circuit and shunt discharge branch

The discharge branch resistance of a single battery connected side by side can be calculated according to the charging voltage of the lithium battery charger, the parameters of the lithium battery and the discharge current. The balancing current should be selected reasonably, if it is too small, the balancing effect is not obvious; if it is too large, the energy loss of the system is large, the balancing efficiency is low, and the thermal management of lithium battery packs is high, the general current size can be designed between 50 and 100 mA.

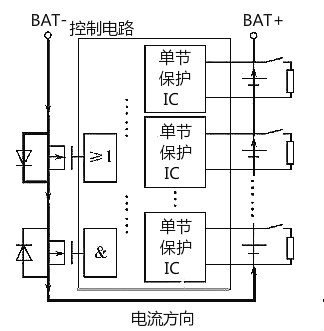

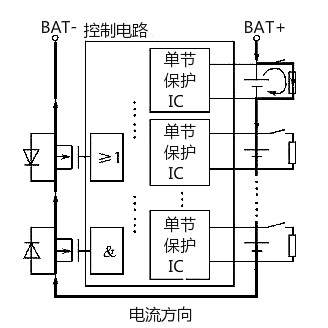

2.3 Discharge Circuit

When the battery discharges, the external load connects the positive and negative BAT + and BAT - terminals respectively. The discharge current flows through the negative BAT-, charge control switch, discharge control switch, single lithium battery N~1 and positive BAT of the battery pack.+The current flow is shown in Figure 4. In the equalization principle system of lithium battery protection board, the control signals of discharge under-voltage protection, over-current and short-circuit protection of a single lithium battery protection chip in the control circuit are output in series after optocoupler isolation, providing gate voltage for the conduction of discharge switch devices in the main circuit; once the battery pack encounters a special case of single lithium battery under-voltage or over-current and short-circuit in the discharge process, corresponding measures are taken. The control signal of discharge protection for single lithium battery becomes lower, and it can not provide gate bias for the discharge control switch device in the main circuit to turn it off and the main circuit is disconnected, that is to say, the process of discharge operation is terminated.

Fig. 4 Battery discharging circuit

Generally, the constant current-constant voltage (TAPER) charging control is adopted for lithium batteries. When charging at constant voltage, the approximate exponential law of charging current decreases. In the system, the switching devices of charge and discharge main circuit can be selected according to the maximum working current and working voltage that the external circuit requirements meet.

The single lithium battery protection chip of the equalization principle control circuit of lithium battery protection board can be selected according to the voltage level and protection delay time of the single lithium battery to be protected. The branch resistance of shunt discharge can be realized by power resistance or resistance network. It is reasonable to adopt resistance network to realize branch resistance of shunt discharge, which can effectively eliminate the influence of resistance deviation and reduce thermal power consumption.

3-Balanced Charging Protection Board Circuit Simulation

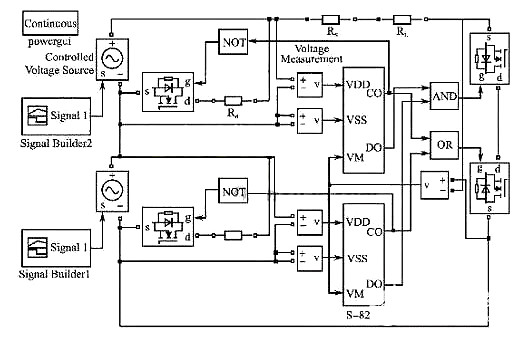

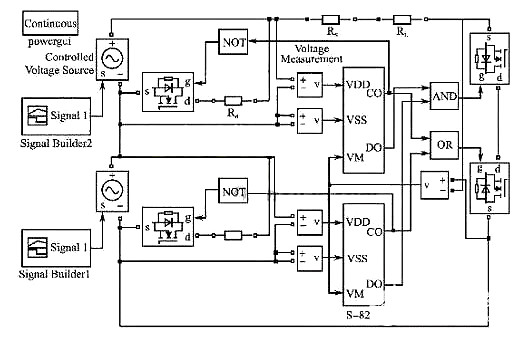

According to the above-mentioned equalization principle of lithium battery protection board, a system simulation model is built under the environment of Matlab/Simulink to simulate the operation of the protection board during the charging and discharging process of lithium battery pack, and to verify the feasibility of the design scheme. For simplicity, a simulation model of lithium battery pack connected in series by only two lithium batteries is given, as shown in Fig. 5.

Fig. 5. 2 Simulation Model of Lithium Battery Charging and Protection in Series

In the model, a controlled voltage source is used instead of a single lithium battery to simulate the charging and discharging of the battery. In Fig. 5, Rs is the total internal resistance of batteries in series, RL is the load resistance, and Rd is the branch resistance of shunt discharge. The single lithium battery protection chip S28241 is packaged as a subsystem, which makes the overall model more concise.

The subsystem model of protection chip based on the equalization principle of lithium battery protection board mainly simulates the timing and logic of protection action by logic operation module, symbol function module, one-dimensional table-looking module, integration module, delay module, switch module and mathematical operation module. Because of the difference between simulation environment and real circuit, there is no need for filtering and strong and weak current isolation in simulation, and redundant modules easily lead to long simulation time. Therefore, in the actual simulation process, filter, optocoupler isolation, level conditioning and other circuits are removed, and the resistance network designed for large current shunt is changed to a single resistance, which reduces the complexity of the simulation system. When building a complete system simulation model, we should pay attention to the difference between input and output data and signal types of different modules. We must arrange the connection order of modules correctly, and convert data types when necessary. In the model, we use voltage detection module to realize the conversion and connection of strong and weak signals.

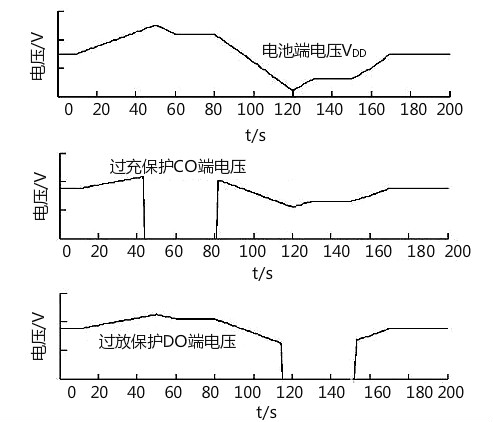

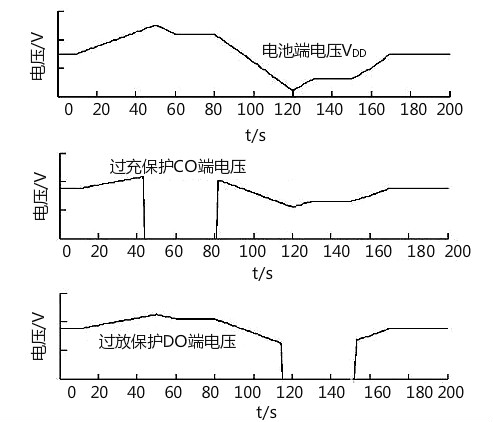

The given signal of the controlled voltage source in the simulation model of the equalization principle of lithium battery protection plate can be slightly different on the premise that the waveforms of the controlled voltage source are basically the same, so as to represent the difference of individual charge and discharge of the battery. Fig. 6 is the simulation result of single cell voltage detection in battery pack. It can be seen that the circuit can work normally by charging the overcurrent discharge branch equally.

Fig. 6 Simulation results of lithium battery voltage detection

4 System Experiments

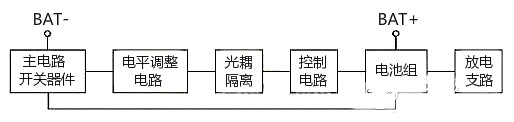

In practical application, according to the demand of a brand electric bicycle manufacturer, two sets of 36V8A.h lithium manganate power battery protection boards in parallel and 10 in series are designed and implemented. The single lithium battery protection chip adopts S28241 of Japan Seiko Company. The protection board mainly consists of main circuit, control circuit, shunt discharge branch circuit, filter circuit, optocoupler isolation circuit and level conditioning circuit. The basic structure of the equalization principle of lithium battery protection plate is shown in Fig. 7. The current of discharge branch is about 800 mA and 510 & Omega is adopted. Resistors are connected in series and parallel to form resistance network.

Figure 7 Lithium battery protection panel debugging

The debugging work is mainly divided into two parts: voltage test and current test. Voltage testing includes two steps: charging performance detection overvoltage, charging equalization and discharging performance detection undervoltage. Battery analog power supply can be chosen to replace the actual battery pack for testing. Because of the series connection of multiple batteries, the test cost of this scheme is relatively high. The assembled battery pack can also be used for direct testing, cyclic charging and discharging of the battery pack, observing the normal operation of the protection device when overvoltage and undervoltage occur, recording the real-time voltage of each battery when overcharge protection occurs, and judging the performance of balanced charging. But this scheme takes a long time to test at one time. When testing the charging performance of batteries, the charging voltage of 10 batteries is monitored by a 3-bit semi-precision voltmeter. It can be seen that all batteries are within the normal working voltage range, and the difference between the individual batteries is very small. The voltage deviation during charging is less than 100 mV.The full charge voltage is 4.2V and the voltage deviation is less than 50mV. The current test includes two steps: overcurrent detection and short circuit detection. Overcurrent detection can connect a ammeter in series between the resistor load and the power supply circuit to reduce the load slowly. When the current increases to the overcurrent value, it can see whether the ammeter indicates the current cut-off. Short circuit detection can directly connect the positive and negative poles of battery pack to observe the ammeter state. On the premise that the device is in good condition and the circuit is welded correctly, the current can also be measured directly by the status of the power indicator on the protective board.

In practical use, considering that external interference may cause unstable battery voltage, which will result in over-voltage or under-voltage for a very short time, leading to wrong judgment of battery protection circuit. Therefore, the protection chip is equipped with corresponding delay logic, and when necessary, the delay circuit can be added to the protection board, which will effectively reduce the external interference and cause the wrong operation of the protection circuit. Possibility. When the system is working, the main loss is the on-state loss of two MOS transistors in the main circuit. When the equalization circuit is working under the charging state, the resistance heat loss in the shunt branch is larger, but the time is shorter, and the overall dynamic loss can be in the normal working cycle of the battery. The level of acceptance.

The test results show that the design of the protection circuit can meet the protection needs of series lithium batteries. The protection function is complete. It can reliably protect overcharge and overdischarge, and realize the balanced charging function at the same time.

According to the need of application, the equalization principle of lithium battery protection board can protect and equalize the power lithium battery packs of any structure and voltage level after changing the type and number of protection chips, power levels of switching devices and energy-consuming elements in the circuit. For example, using FS361A single lithium battery protection chip of Taiwan Fujing Company, three groups of parallel connection and 12 series of lithium iron phosphate battery protection board design can be realized.

The reason why lithium batteries (rechargeable) need protection is determined by their own characteristics. Because the material of lithium battery itself determines that it can not be overcharged, overdischarge, overcurrent, short circuit and ultra-high temperature charging and discharging, lithium battery lithium components will always follow a delicate protective board and a current safety device.

1. Normal state

In the normal state of the circuit, N1's“ CO” and“ DO” both of the feet output high voltage, and the two MOSFETs are in the on-state. The batteries can charge and discharge freely. Because the on-resistance of the MOSFET is very small, usually less than 30 milliohms, its on-resistance has little influence on the performance of the circuit.

Under this condition, the consumption current of the protection circuit is & mu; A, usually less than 7 & mu; A.

2. Overcharging protection

The charging mode of lithium-ion batteries is constant current/constant voltage. In the initial stage of charging, the charging mode is constant current. With the charging process, the voltage will rise to 4.2V (according to different cathode materials, some batteries require constant voltage value of 4.1V), and then change to constant voltage charging until the current is getting smaller and smaller.

When the battery is charged, if the charger circuit is out of control, it will continue to charge at constant current after the battery voltage exceeds 4.2V. At this time, the battery voltage will continue to rise. When the battery voltage is charged to more than 4.3V, the chemical side effects of the battery will intensify, which will lead to battery damage or safety problems.

In the batteries with protective circuits, when the control IC detects that the battery voltage reaches 4.28V (which is determined by the control IC and different IC has different values), its & ldquo; CO” feet will be changed from high voltage to zero voltage, so that T1 will be turned off from conduction, thus cutting off the charging circuit and making the charger unable to recharge the batteries and overcharge them. Electrical protection. At this time, due to the existence of the body diode VD1 in T1, the battery can discharge the external load through the diode.

There is a delay time between the detection of battery voltage exceeding 4.28V and the signal of turning off T1 in the control IC. The delay time is determined by C2, usually set to about 1 second, in order to avoid misjudgment caused by interference.

3. Overdischarge protection

When the battery voltage drops to 2.5V, its capacity has been fully irradiated. At this time, if the battery continues to discharge on the load, it will cause permanent damage to the battery.

In the process of battery discharging, when the control IC detects that the battery voltage is less than 2.3V (which is determined by the control IC and different IC has different values), its & ldquo; DO & rdquo; feet will change from high voltage to zero voltage, so that T2 will be turned off from conduction, thus cutting off the discharge circuit, so that the battery can no longer discharge the load and play an overdischarge protection role. At this time, due to the existence of the body diode VD2 in T2, the charger can charge the battery through the diode.

Because the battery voltage can not be reduced under over-discharge protection, the consumption current of the protection circuit is very small. At this time, the control IC will enter a low power state, and the power consumption of the whole protection circuit will be less than 0.1 & mu; A. There is also a time delay between the detection of battery voltage below 2.3V and the sending of turn-off T2 signal in the control IC. The time delay is determined by C2, usually set to about 100 milliseconds, in order to avoid misjudgment caused by interference.

4. Overcurrent protection

Due to the chemical characteristics of lithium-ion batteries, battery manufacturers have stipulated that the maximum discharge current should not exceed 2C (C = battery capacity/hour). When the discharge current exceeds 2C, the battery will cause permanent damage or safety problems.

When the discharge current passes through two MOSFETs in series during the normal discharge of the battery to the load, a voltage will be generated at both ends of the MOSFET due to the conduction impedance of the MOSFET, which is U=I*RDS*2.RDS is the conduction impedance of a single MOSFET, which controls the “ V-&rdquo on the IC. The foot detects the voltage value. If the load causes abnormalities and increases the circuit current, when the circuit current is large enough to make U> 0.1V (the value is determined by the control IC, different IC has different values), its “ DO” foot will change from high voltage to zero voltage, so that T2 will be turned off from conduction to off, and from U> to 0.1V. The discharge circuit is cut off, so that the current in the circuit is zero, playing the role of over-current protection.

There is also a time delay between the detection of overcurrent in control IC and the sending of turn-off T2 signal. The time delay is determined by C2, usually about 13 milliseconds, in order to avoid misjudgment caused by interference.

In the above control process, it can be seen that the magnitude of the overcurrent detection value depends not only on the control value of the control IC, but also on the conduction impedance of the MOSFET. The larger the conduction impedance of the MOSFET, the smaller the overcurrent protection value of the same control IC.

5. Short circuit protection

When the circuit current of the battery is large enough to make U> 0.9V (which is determined by the control IC and different IC has different values), the control IC is judged to be short circuit of the load, and its & ldquo; DO” feet will rapidly change from high voltage to zero voltage, so that T2 will be turned off from conduction, thus cutting off the discharge circuit and playing a short circuit protection role. The delay time of short circuit protection is very short, usually less than 7 microseconds. Its working principle is similar to that of over-current protection, but the judgment method is different, and the protection delay time is also different.

6 Conclusion

In this paper, a single lithium battery protection chip is used to design and implement a series of battery pack protection boards. In addition to the necessary over-voltage, under-voltage, over-current and short-circuit protection functions, the balanced charging function can also be realized. The simulation and experimental results verify the feasibility of the scheme, and the stability of the design is verified by the market usage.

Industry developments

Industry developments

Li Tongwei Electronics Technology Co., Ltd. was established on September 29, 2005. It is a professional lithium-battery protection module, lithium-powered battery protection module, single-chip microcomputer control intelligent lithium-powered battery balance protection module, battery management system(BMS), and lithium battery terminal application product UPS, emergency power supply, automotive backup power supply, Mobile base station, electric vehicle BMS, mobile power supply and other R&D, production, sales and service of national high-tech enterprises.

The company has now passed the ISO 9001:2015 quality management system, the ISO 14001:2015 environmental quality management system, the QC080000 harmful substances management system,...

Li Tongwei Electronics Technology Co., Ltd. was established on September 29, 2005. It is a professional lithium-battery protection module, lithium-powered battery protection module, single-chip microcomputer control intelligent lithium-powered battery balance protection module, battery management system(BMS), and lithium battery terminal application product UPS, emergency power supply, automotive backup power supply, Mobile base station, electric vehicle BMS, mobile power supply and other R&D, production, sales and service of national high-tech enterprises.

The company has now passed the ISO 9001:2015 quality management system, the ISO 14001:2015 environmental quality management system, the QC080000 harmful substances management system,...